This is cool. Though deals with a lot of different processes with acid and likely mechanical (crushing milling the electronics).

And they determined this by making $34 in gold (today’s prices), so it’d really have to be huge scale to make $$.

I also wonder if they evaluated the cost of disposal of all the remaining material and acid baths in their cost analysis.

Yeah, and is the cost of disposal a recycling process, or dumping the leftovers in the local river? Because you know that if they can make it $35 by doing the latter, those rivers are fucked.

“scientist’s calculations reveal that the procurement costs of the source materials and the energy cost of the entire extraction process are 50 times lower than the value of the gold that can be recovered. “

If we assume that “source materials” cover the circuit boards, whey, acids and any other chemicals, then byproduct processing and waste disposal hasn’t been addressed in any way. What’s the processing plant supposed to do anything that isn’t gold, silver or copper?

Anyway, this technique could work in tandem with a normal circuit board leaching plant. If you already have a factory for processing this sort of feed material, you could try to reduce the cost of operating one of the steps by using whey sponge instead.

As someone who has personally mined 2.5g of gold from old electronics, I can confirm that while messy, there are no toxic byproducts.

In my setup, the only waste was hydrogen gas, CO2, and NaCl.

Of course I preprocessed my electronics to remove any solder or components, and you’re still left with the bare fiberglass circuit boards, so it may be different on an industrial scale.

This is the first time I’m hearing of e waste mining, do you recommend doing it at a small scale? and if so, do you need any special material for the set up?

It’s a lot of work. At the end of the day, I spent about $1k to get about $100 worth of gold, so it’s really not lucrative. I just wanted a fun story behind an engagement ring.

I actually mined the gold from electronics and those gold plated Pokémon cards they sold at Burget King for Pokémon the Motion Picture, but that’s another process.

Here’s how it goes:

-

Clean up your electronics. You ideally want just circuit board contacts. Like the strip of contacts on a stick of ram. Cut/break those off and dispose of the rest.

-

Soak in copper chloride. Use Hydrochloric acid (sold as concrete cleaner) and hydrogen peroxide. It’ll start eating at the copper on the circuit boards. 2HCl + H2O2 + 2Cu -> 2CuCl + 2H2O

-

Keep dissolving. This part takes a while. It helps to use a stir bar and bubbler to keep the fluid moving. CuCl will eat more copper and produce CuCl2, but you can “recharge it” by adding more HCl and bubbling in oxygen (or use hydrogen peroxide, but that’s more expensive).

-

Now you should have a bunch of flakes of gold that was plated onto the copper as well as the bare circuit boards floating around in a dark green solution of copper chloride. Pour through a coffee filter and wash with water to remove all the copper chloride.

-

To recycle the copper chloride, mix with sulfuric acid (sold as battery acid). CuCl + H2SO4 -> HCl + CuSO4. Boil off and condense the HCl to re-use. You won’t be able to get “fuming” 30% stuff like you buy at the store because the azeotrope of HCl is 20%. Then you can plate out the copper from the copper sulfate and reuse the resulting sulfuric acid. Copper sulfate is a super pretty blue by the way.

You do copper sulfate because plating copper out of CuCl2 will release HCl gas which is nasty.

- Now you have to extract the gold from all the random bits of circuit boards. Mix Nitric acid and more HCl to make “aqua regia.” Gold is slightly soluble in HNO4, but it’ll the get stolen by the HCl to make “chloroauric acid” which looks exactly like piss. Nitric acid is the only ingredient that’s hard to get. I found a seller on eBay, but there are also methods for manufacturing it at home from other compounds.

- Wash/filter the components like you did with the copper chloride to get all the chloroauric acid out. Then sprinkle some sodium metabisulfite in which will react with the nitric acid and produce sulfur dioxide gas which reacts with the chloroauric acid to make metallic gold, sulfuric acid, and Hydrochloric acid.

Filter through another coffee filter and distill resulting solution to recover HCl and H2SO4.

- At this point the gold is an insanely fine powder. Like it’ll take hours just to settle to the bottom of the solution. I ended up having to filter it several times to get it all out.

Dry the filter paper, ball it up, and toss it in a heated crucible (I used a blow torch) with some borax to act as a flux. Eventually the paper burns away and you’re left with a tiny bead of gold.

So yeah, you can reuse the copper, Hydrochloric acid, and sulfuric acid, and the other byproducts are harmless salts and gases.

Thanks so much for sharing and taking the time to break it down for the layperson!

-

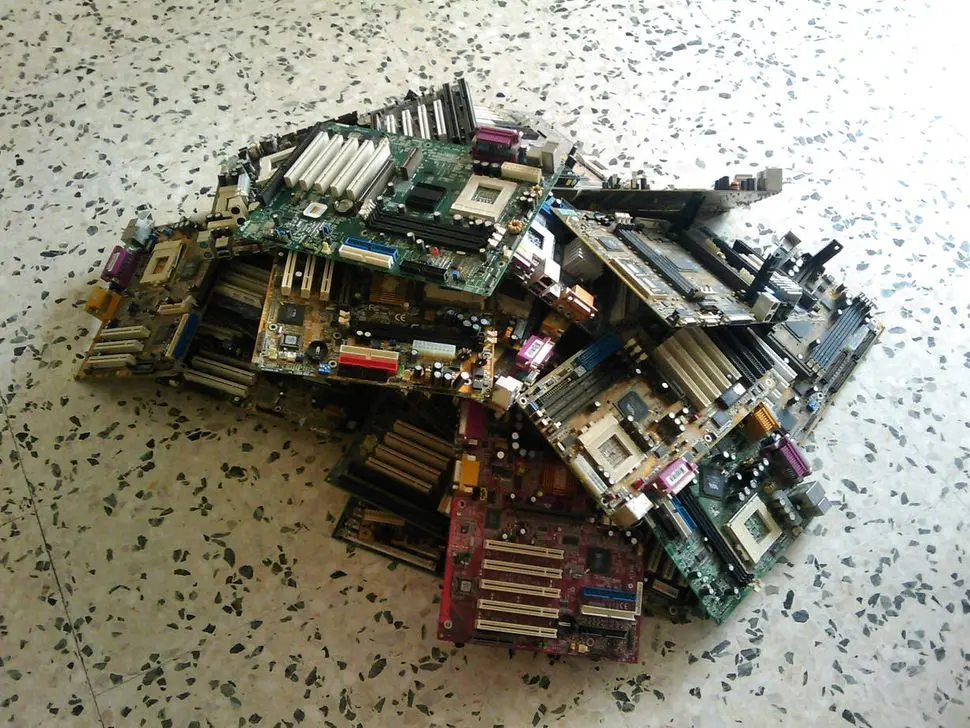

I don’t suppose you would mind laying out your process? This sounds fascinating (and I have a lot of old motherboards)

This is a huge win compared to gold mining.

Gold mining is using cyanure and caustic soda (in the best case, the worst case is using boiling mercury)

Is this something your average person could do?

TIL I’m a robot because whey protein really messes me up too. I have some captchas to apologise to.

Try Isolate instead of concentrate, I cant have concentrate. My wife wil divorce me and I might gas the dog.

I was mainly thinking in terms of its use as a cheap bulking agent in food rather than as a nutritional supplement. If I tried a straight supplement, I fear Violet Beauregarde’s transformation would have nothing on what would happen.

This is pretty great. Staff sometimes ask me at work if we recycle old electronics, to which I can truthfully say yes. I don’t mention that the recycling process begins by soaking it all in acid…

Is it better than just burning/burying it?

Some of the chemicals that go into making circuit boards are pretty nasty too. When I was learning about them, arsenic was a component of semiconductors. I don’t know much about the chemistry, but I think having that in your air or leaching into your groundwater would be bad news.

Is gold the only thing worth recovering from electronics? Or just the most valuable?

The most valuable and easily collected.

Chips have many metals in them and sometimes extremely rare metals. Silver, gold, indium, titanium, tungsten, etc all are used to some degree. Among many others, (those are just metals that I personally have experience in, in semiconductors)

Tantalum in yellow capacitors IIRC

Yo so I got a tub of this whey protein powder, how do I make one of these sponges?

Gains

deleted by creator